Pipeline renovation

PIPE AND SEWER RENOVATION

The methods we use for sewer, pipe and shaft rehabilitation are characterized by minimal excavation work. This saves time and money. The result is particularly beneficial for the environment, as possible wastewater leaks and/or groundwater ingress can be remedied much more efficiently than with a conventional excavation method.

An additional advantage is a significantly reduced interruption to supply and disposal, which in turn results in significantly reduced dust and noise emissions and minimized traffic disruption. Likewise, with correct planning, conflicts with other underground installations can be prevented.

For a wide variety of pipe dimensions and shapes

In so-called relining, a basic distinction is made between short and long pipe relining. In both variants, the new pipe is pulled or pushed into the existing pipe, whereby the resulting slight reduction in the pipe diameter is usually compensated for by the better flow properties of the new pipe.

In short pipe relining, individual rigid segments are gradually built into the existing pipe. Circular, egg-shaped and special profiles with a diameter of up to three meters can be installed.

For round pipes up to 500 mm, long pipe relining is generally more economical. The pipes are welded together on site and then pulled into the existing pipe. Due to the flexibility of the pipes, small radii are also possible.

Relining pressure pipes

This refurbishment process is used specifically to refurbish power plant supply lines up to DN 3,000 mm. Coiled pipes made of glass fiber reinforced plastic (GRP) with a length of up to six meters are used. Installation is carried out by inserting special equipment. The annular gap between the old building and the neurotube is filled with concrete without cavities.

Rehabilitation of canals and open channels of all cross-sectional shapes

When renovating canals and open channels, lining with prefabricated polymer concrete profiles is ideal. This process ensures minimal loss of cross-section and the individual components are bonded with a special adhesive. Polymer concrete is a particularly resistant material consisting of silicate rock sands bonded in a polyester resin matrix.

Due to the excellent material properties of polymer concrete, its use is particularly appropriate in areas with the highest mechanical and chemical resistance requirements. In addition, any profile shape can be produced with this type of renovation.

Short construction period — low cross-section reduction

The hose relining process enables trenchless rehabilitation of pressure and free mirror lines, applicable to circular, egg and special profiles. Different methods are used for this purpose. On the one hand, relining with a needle felt liner, on the other hand, the version of the GRP liner.

The advantages of this renovation process include the low cross-section reduction, the short construction period and the flexible range of application.

NEEDLE FELT LINER with epoxy resin and hot water or steam curing

The needle felt hose, impregnated and coated with epoxy resin, is installed using a reversion process (slip process) over existing shafts or, in the case of larger dimensions, over smaller excavation pits using water pressure or compressed air. The pressurized inliner is caused to harden by heating the water or by using hot steam.

The result is a structural liner with low cross-section loss that is comparable to a new pipe. The area of application includes free-mirror pipes in wastewater and industrial sectors with a diameter of 100 to 800 mm. The needle felt liner can be used for all profiles and pipe materials. Only DIBt-approved liner/resin systems are used.

GRP LINER with UV light curing

During renovation with GRP liner, a fibreglass hose impregnated and coated with resin at the factory is inserted into the line to be renovated using a winch and hardened.

Curing is carried out using a chain of UV lights. The liner then forms a system that is equivalent to a neurohr. Depending on the design and static requirements, the GRP liner can completely take over the loads of the old pipe.

The area of application includes free-mirror lines in wastewater and industrial sectors with a diameter of 150 to 2000 mm, such as the needle felt liner. The GRP liner can be used for all profiles and pipe materials.

Quick, selective damage repair

The short liner process (part liner) is a suitable method for selective repair of damage such as root growth, axial and radial cracks, broken pipes, missing wall parts and corrosion damage. The short liner is suitable for renovation lengths of 0.5 to 5 m with pipe diameters of 100 to 600 mm.

A GRP carrier mat soaked in resin is used, which is fixed to a packer. This is then positioned at the damaged area and pressed down to the size of the inner diameter of the existing old pipe. The curing process takes place under continuous pressure until the packer can be removed or withdrawn from the pipeline after successful curing.

REHABILITATION OF NON-ACCESSIBLE CROSS-SECTIONS

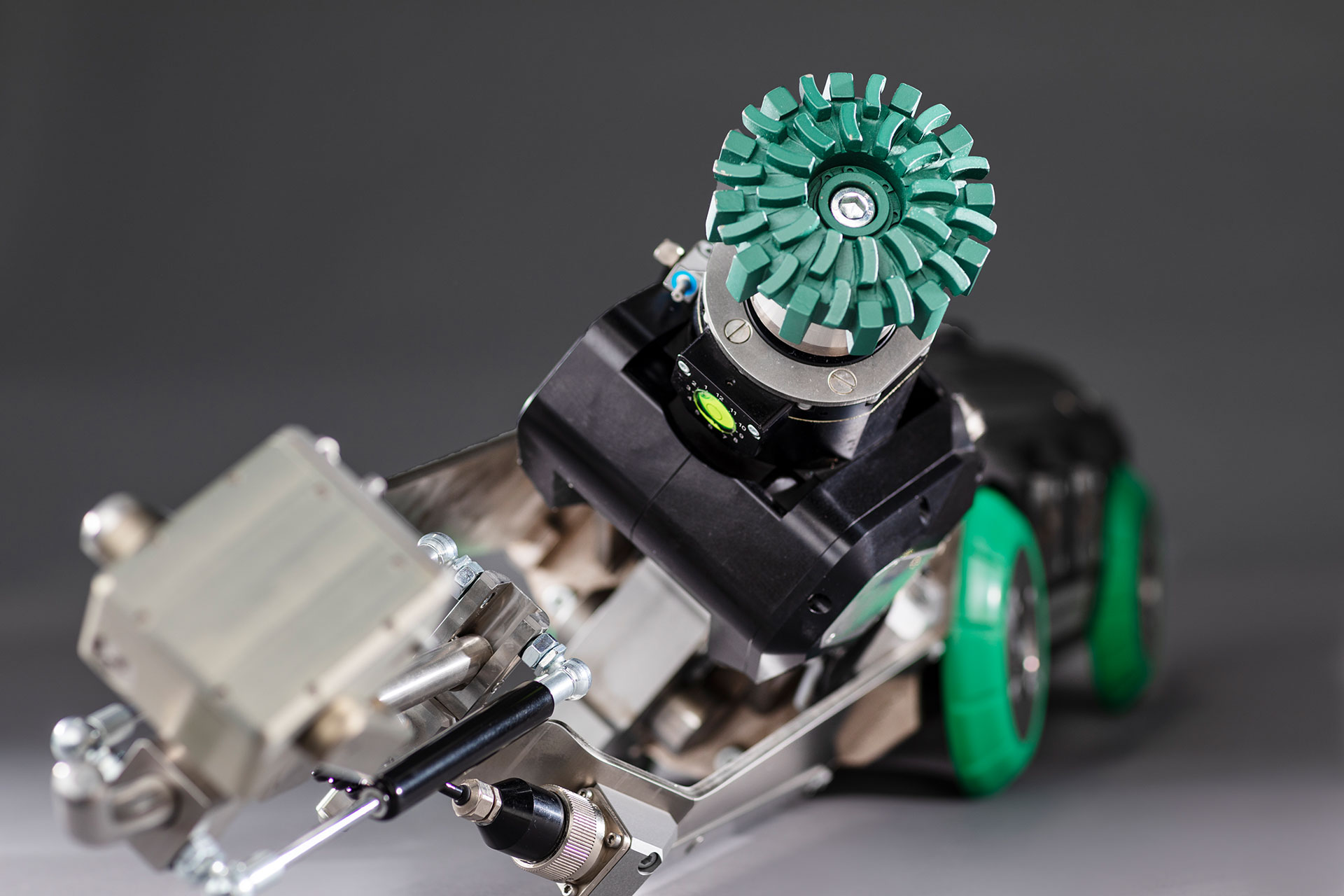

The Sewer Rehabilitation Robot is used when the rehabilitation work is not possible or too dangerous for humans. In addition to traditional processes such as milling, grinding and drilling, the robot is also suitable for filling cracks and holes. Inlets or defective branches that are not properly connected can also be tightly integrated into the sewage system.

Our renovation robot is versatile: In addition to milling channels, it also enables repair work, pre-milling postures for inline installation, and milling and filling cracks or leaky sockets.

FOR AN ALL-ENCOMPASSING Leakproof SYSTEM

The renovation of damaged buildings, in particular wastewater disposal and drinking water supply systems, is also an essential part of our service portfolio. Depending on the type of damage, we offer a wide variety of methods for repairing buildings.

SHAFT FRAME RENOVATION

Manhole covers can sag or grow out as a result of external loads and pose a hazard in road areas.

Our manhole renovation processes make it possible to raise or lower manhole covers that are too low with little effort. With an average renovation time of a maximum of one hour, we can quickly and easily renovate manhole covers that are too low or too high with minimal traffic disruption.

The advantages of shaft frame renovation include short construction time, low dust and noise pollution for residents and no scraping or asphalting work.

The potting material used is early-resistant, shrink-free and resistant to frost and de-icing salt, which guarantees long-lasting renovation success. The manhole cover can be loaded again after a very short time and released for traffic.

BUILDING RENOVATIONS — COATINGS

By coating shafts, containers and pipes, the ingress of groundwater and the escape of dirty water can be prevented. At the same time, the chemical and mechanical resistance of the surface is increased.

Substrate preparation is carried out by high-pressure water blasting or sandblasting and forms the basis for subsequent corrosion protection, reprofiling and coating work. Depending on the application, the coating is carried out by centrifugal or wet spraying or manually. Cement-bound, sulfate-resistant and drinking-water-compatible building materials with appropriate suitability for the respective application are primarily used.

The advantages of this rehabilitation process are the absolute tightness of the sewage system and a slight reduction in the discharge cross section of the sewers.

SELECTIVE REMEDIATION — INJECTIONS

The wide range of different injection methods enables targeted treatment of individual damage patterns of buildings.

Injections are used primarily in concrete and brick buildings, in particular when rehabilitating sewer profiles, shafts, cellars and other structures to prevent groundwater ingress.

Special reaction resins are injected into the cavity using injection packers, which react with water and foam up, which permanently and elastically seals the leak.

PARTIAL RENOVATION/LINER CONNECTION

The Quick-Lock stainless steel cuff is a repair process that enables more than just a partial renovation. The Quick-Lock system, consisting of a V4A stainless steel sleeve and EPDM, silicone or NBR seal, seals and stabilizes the damage pattern purely mechanically, without construction chemicals and regardless of the pipe material.

After renovation, the stainless steel cuff remains elastically supported and absorbs movements of the pipes. In case of longer damage patterns, the Quick-Lock cuffs are placed in series one after the other. The cuffs in nominal sizes DN 150 mm to DN 800 mm are positioned centrally above the damage using the Quick-Lock offset packer.

The BIG collars with nominal widths of DN 800 mm to DN 3000 mm are clamped with a manual adjustment tool in the pipe to be renovated and also aligned centrally over the damage. The specially developed locking mechanism is suitable for heavy use, and therefore also for high-pressure applications.

Renewal in the same channel

Pipe bursting is one of the most eco-friendly methods of renewing buried pipelines. In this process, the existing pipe is destroyed using a cutting blade and then driven out into the surrounding soil. The new pipe is inserted at the same time. Depending on the conditions of the ground, this technique allows up to 200 metres of pipe to be replaced every day – and for the cross-section of the pipe to be increased by up to two dimensions.

This pipeline renovation method is suitable for pipes measuring 65 to 800 millimetres in diameter and can be employed both for general channels and for gas and water pipes.

reports and references

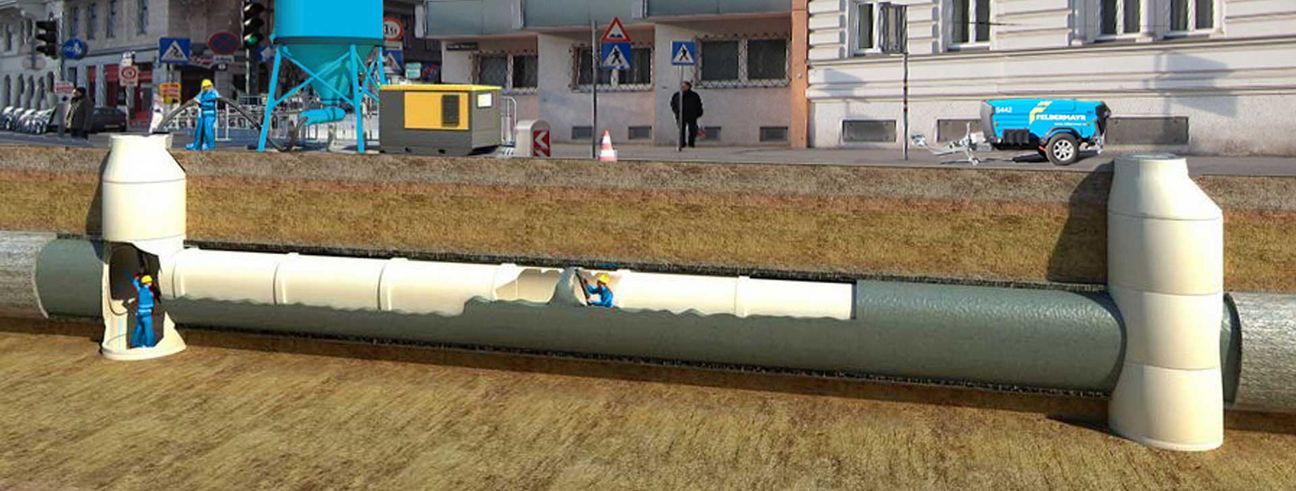

Sewer rehabilitation using a “pipe-in-pipe” system

In Vienna, an investigation into a sewer system that was over 100 years old revealed an urgent need for renovation and the modern relining process was chosen.

Sewer refurbishment using short pipe relining

Felbermayr used what is called “short pipe relining” to refurbish a sewer in Graz during March. This process enabled a section of sewer approximately 600 m long to be refurbished extremely quickly,…

Felbermayr offers you comprehensive solutions for pipe and sewer rehabilitation. Our expertise and the use of cutting-edge technologies ensure an efficient and sustainable refurbishment of your infrastructure. Benefit from our experience and commitment to quality and environmental protection.

Contact us today to find out more about our services and get a personalized quote. Together, we ensure that your pipe and sewer systems remain functional over the long term and meet the highest standards.